TIRE BUILDING BLADDERS

TIRE BUILDING BLADDERS

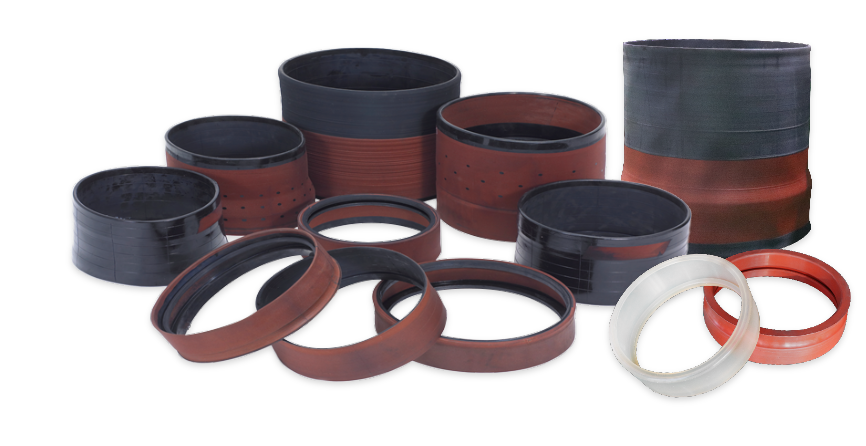

Saerim produces turn up bladders, silicon type of seal bladders, pusher over bladders,

sleeves, drum bands and rubber parts for different tire building machines and the assembly machines.

We produce various types and designs of bladders that cover all tire sizes from car,

truck & bus to off-the-road tires.

We will make it possible to customize the bladders to your special needs in reliable and high quality of products at a competitive price for you.

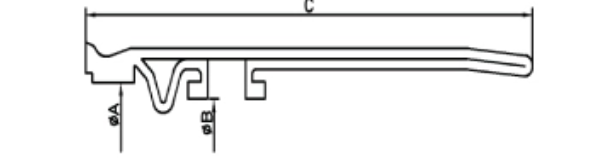

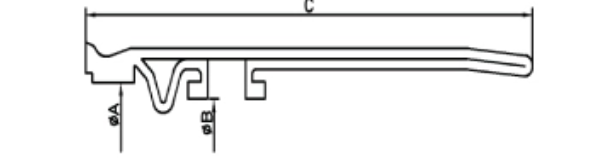

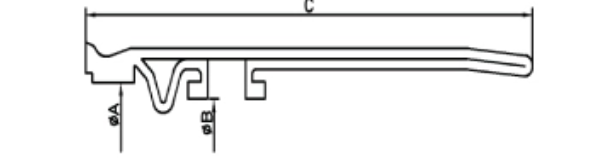

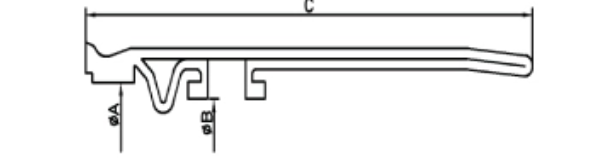

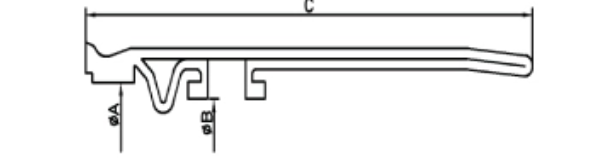

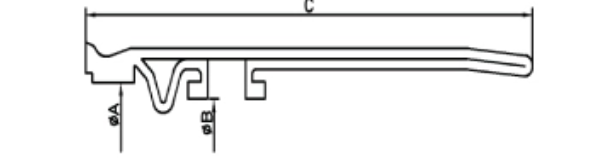

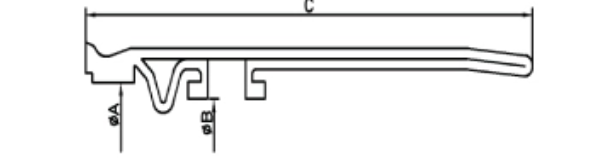

TURN UP BLADDER

TURN UP BLADDER

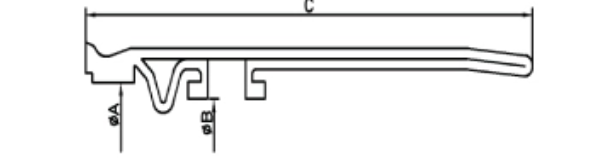

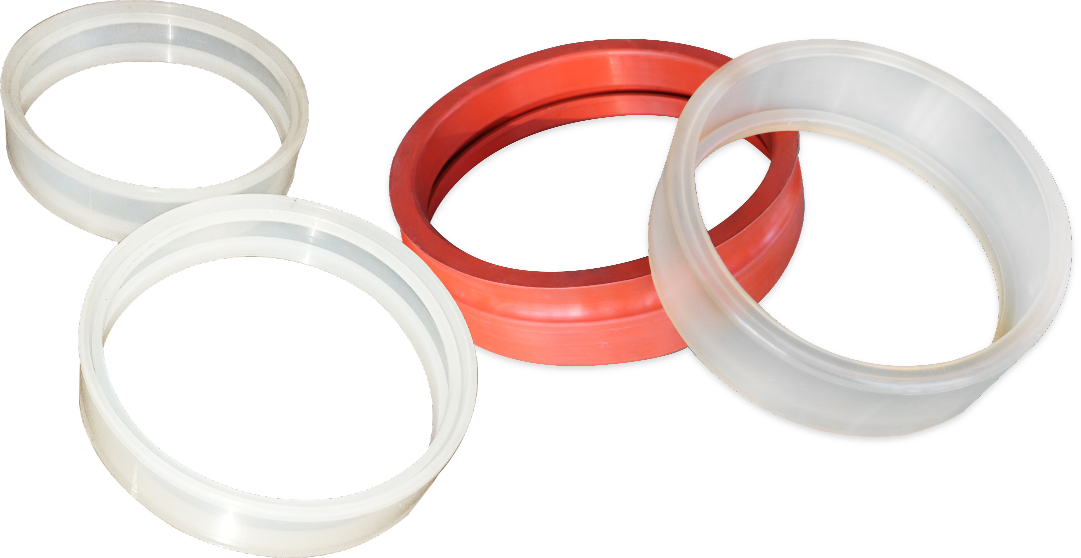

SILICON TYPE (SAEL) BLADDER

SILICON TYPE (SAEL) BLADDER

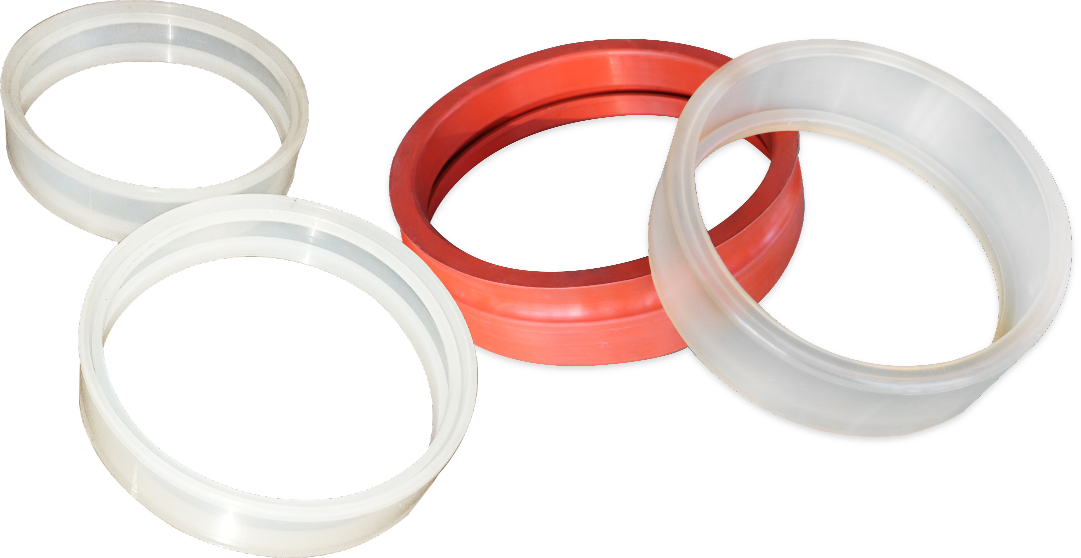

PUSH-OVER BLADDERS

PUSH-OVER BLADDERS

We will make it possible to customize the bladders to your special needs in reliable and high quality of products at a competitive price for you.

TURN-UP BLADDERS

SILICON TYPE (SAEL) BLADDER

PUSH-OVER BLADDERS

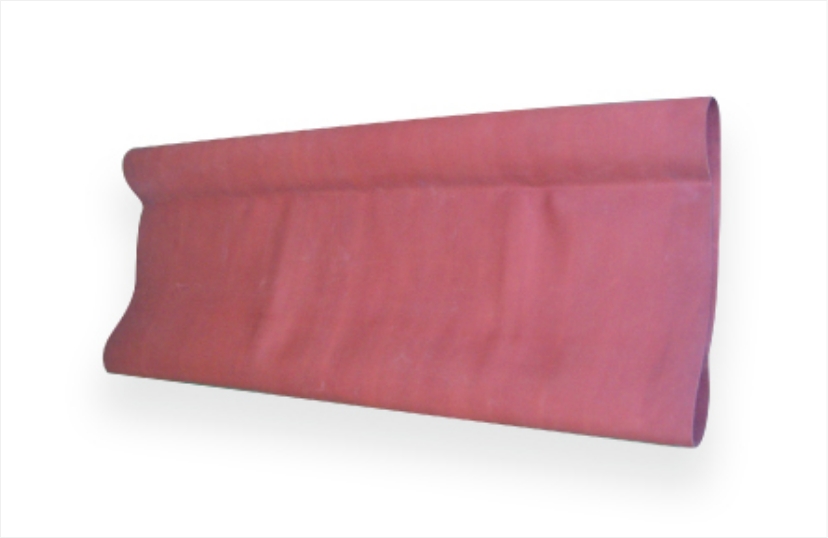

SLEEVES

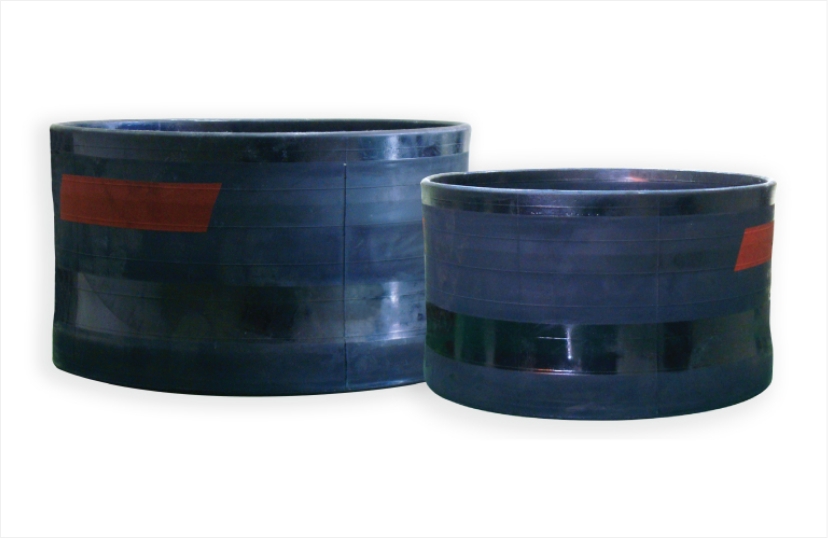

DRUM BAND

AIR CLUTCH BLADDERS

FORM ROLLERS

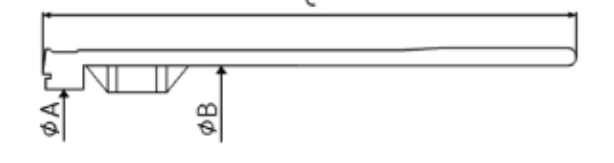

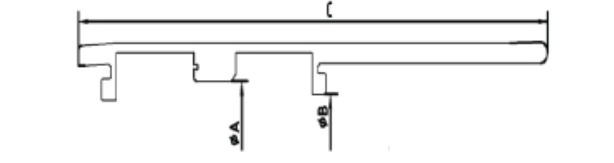

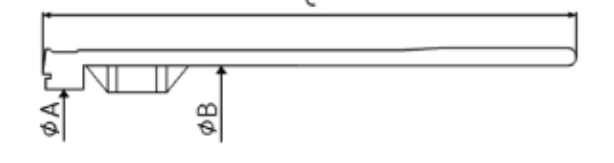

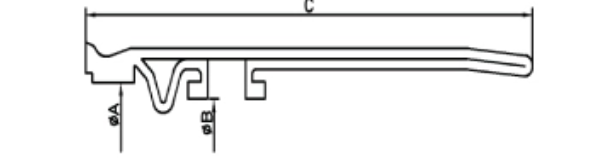

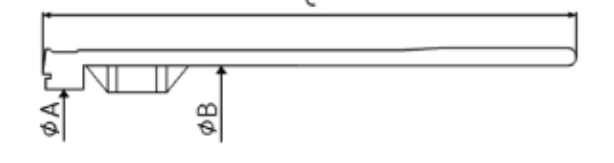

TURN UP BLADDER

TURN UP BLADDER

Tire building bladders are mounted on the tire building machines to support tire building process.

Saerim manufactures turn up bladder, pusher over bladders, sleeves, drum bands and VMI types of mechanical bladders in cooperation with leading tire manufacturers.

Saerim produces variety of tire building bladders with longer lifetime and for consistent tire uniformity, lower cost for the tire manufacturers.

If you are interested in our bladders please contact us. Saerim will make it possible to customize the bladders to your special needs in highly quality and at a competitive price for you.

Saerim manufactures turn up bladder, pusher over bladders, sleeves, drum bands and VMI types of mechanical bladders in cooperation with leading tire manufacturers.

Saerim produces variety of tire building bladders with longer lifetime and for consistent tire uniformity, lower cost for the tire manufacturers.

If you are interested in our bladders please contact us. Saerim will make it possible to customize the bladders to your special needs in highly quality and at a competitive price for you.

| INCH | C | A | B |

|---|---|---|---|

| 13 | 200~260 | 269 | 291 |

| 14 | 294 | 316 | |

| 15 | 320 | 342 | |

| 16 | 345 | 367 | |

| 17 | 371 | 393 | |

| 18 | 394 | 418 |

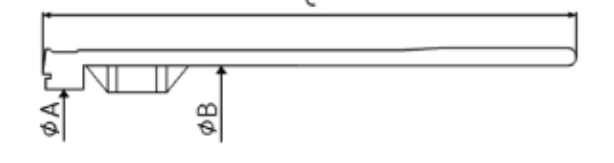

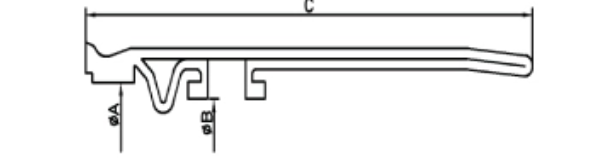

| INCH | C | A | B |

|---|---|---|---|

| 14 | 310 | 395 | 284 |

| 15 | 320 | 308 | |

| 16 | 344 | 333 | |

| 17 | 375 | 366 | |

| 18 | 399 | 390 |

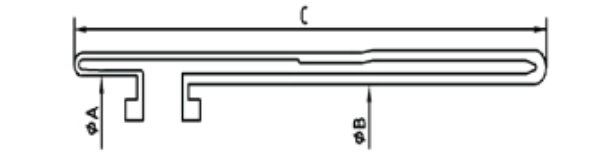

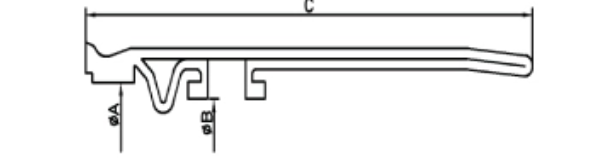

| INCH | C | A | B |

|---|---|---|---|

| 13 | 200~240 | 291 | 285 |

| 14 | 316 | 310 | |

| 15 | 341 | 335 | |

| 16 | 366 | 363 |

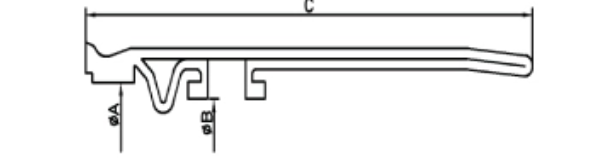

| INCH | C | A | B |

|---|---|---|---|

| 22 | 344 | 450 | 429 |

| 22.5 | 461 | 442 | |

| 24 | 494 | 481 |

| INCH | C | A | B |

|---|---|---|---|

| 17" | 200~260 | 344 | 332 |

| 18" | 369 | 316 | |

| 19" | 320 | 342 |

| INCH | C | A | B |

|---|---|---|---|

| 22.5 | 405 | 424 |

| INCH | C | A | B |

|---|---|---|---|

| 19.5 | 93 | 408 | 384 |

| INCH | C | A | B |

|---|---|---|---|

| 17 | 279 | 374 | 387 |

| INCH | C | A | B |

|---|---|---|---|

| 15 | 305 | 291 | 285 |

| 16 | 316 | 310 | |

| 17 | 341 | 335 | |

| 18 | 366 | 363 |

| INCH | C | A | B |

|---|---|---|---|

| 49 | 1153 | 1068 | 1076 |

| INCH | C | A | B |

|---|---|---|---|

| 16 | 61 | 327 | 277 |

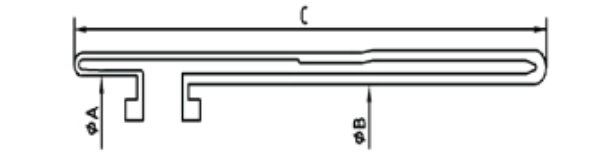

SILICON TYPE (SAEL) BLADDER

SILICON TYPE (SAEL) BLADDER

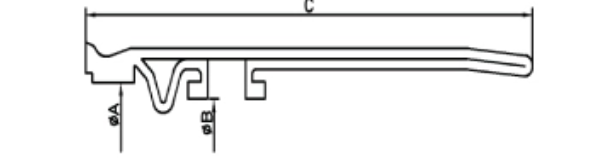

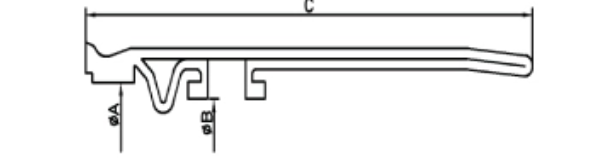

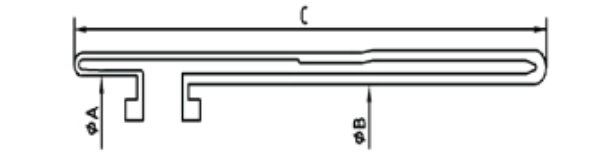

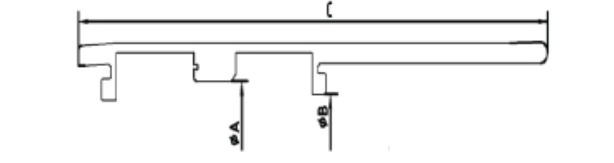

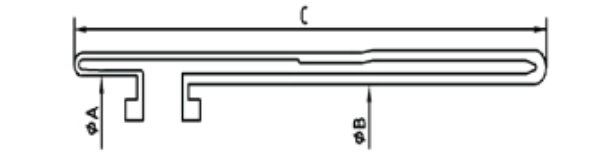

PUSH-OVER BLADDERS

PUSH-OVER BLADDERS

| INCH | C | A | B |

|---|---|---|---|

| 13 | 175~215 | 266 | 279 |

| 14 | 291 | 304 | |

| 15 | 317 | 330 | |

| 16 | 342 | 355 | |

| 17 | 368 | 381 |

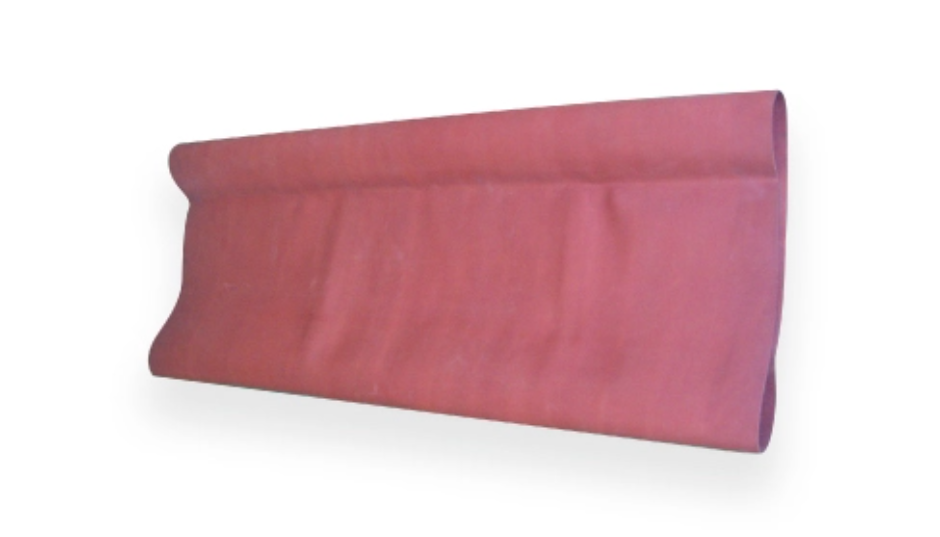

SLEEVES

SLEEVES

| DIAMETER (INCH) | WIDTH |

|---|---|

| 15 | 1300mm for 15" |

| 16 | 1445mm for 16" |

| 17 | 1150mm for 17"~20" |

| 18 | 1150mm for 17"~20" |

| 19 | 1150mm for 17"~20" |

| 20 | 1150mm for 17"~20" |

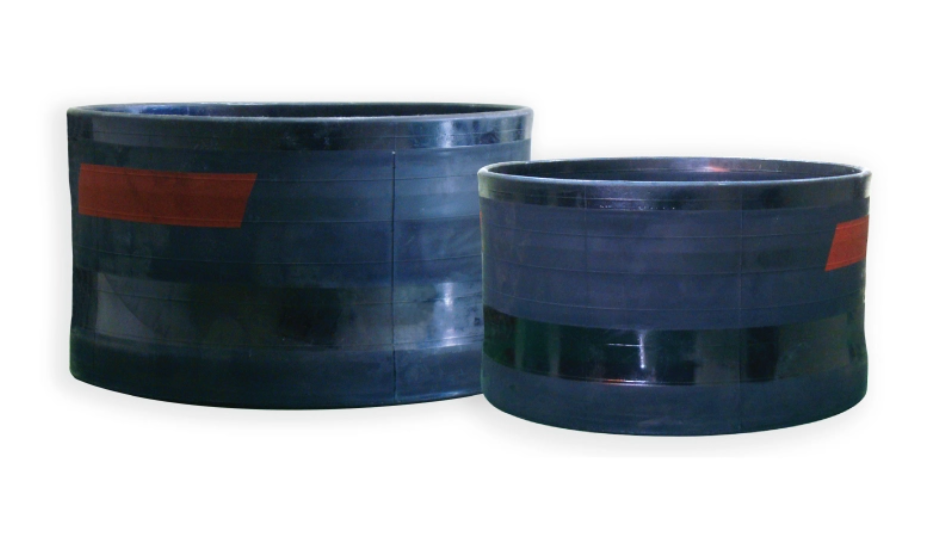

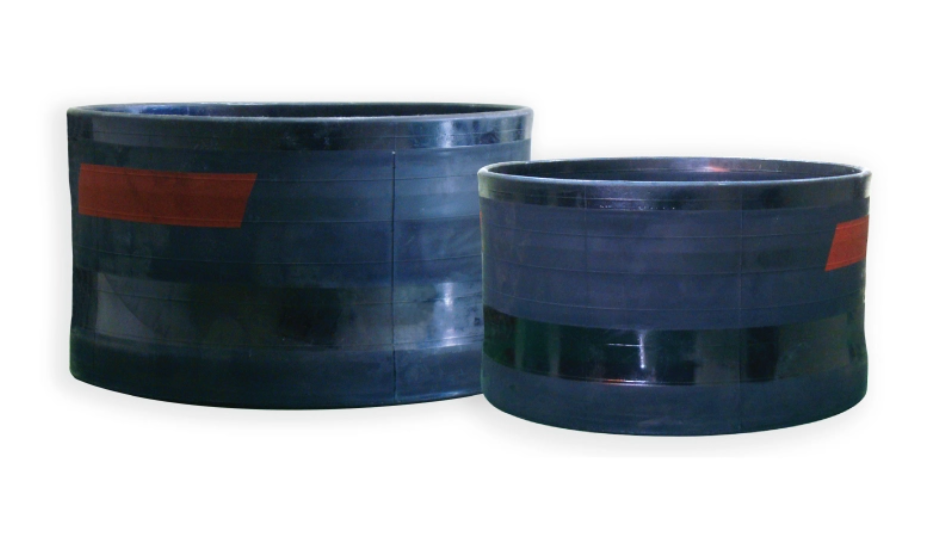

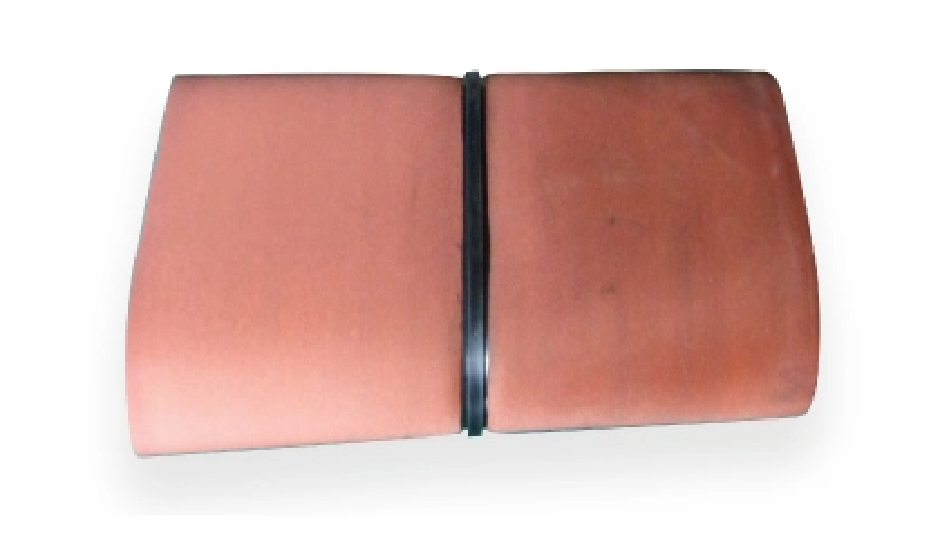

DRUM BAND

DRUM BAND

| DIAMETER (INCH) | WIDTH |

|---|---|

| 15 | 1300mm for 15" |

| 16 | 1445mm for 16" |

| 17 | 1150mm for 17"~20" |

| 18 | 1150mm for 17"~20" |

| 19 | 1150mm for 17"~20" |

| 20 | 1150mm for 17"~20" |

DRUM BAND

DRUM BAND

Air clutches are commonly used and suitable for various applications and industries.

We developed rubber-type air clutch which can be separated from drum and rubber part, which is beneficial

for tire production cost reduction.

The rubber type air clutches play critical roles by providing precise control of speed that used for tire production for tire building and calendaring machines, tire testing equipment and various torque transmission, etc.

The rubber type air clutches play critical roles by providing precise control of speed that used for tire production for tire building and calendaring machines, tire testing equipment and various torque transmission, etc.

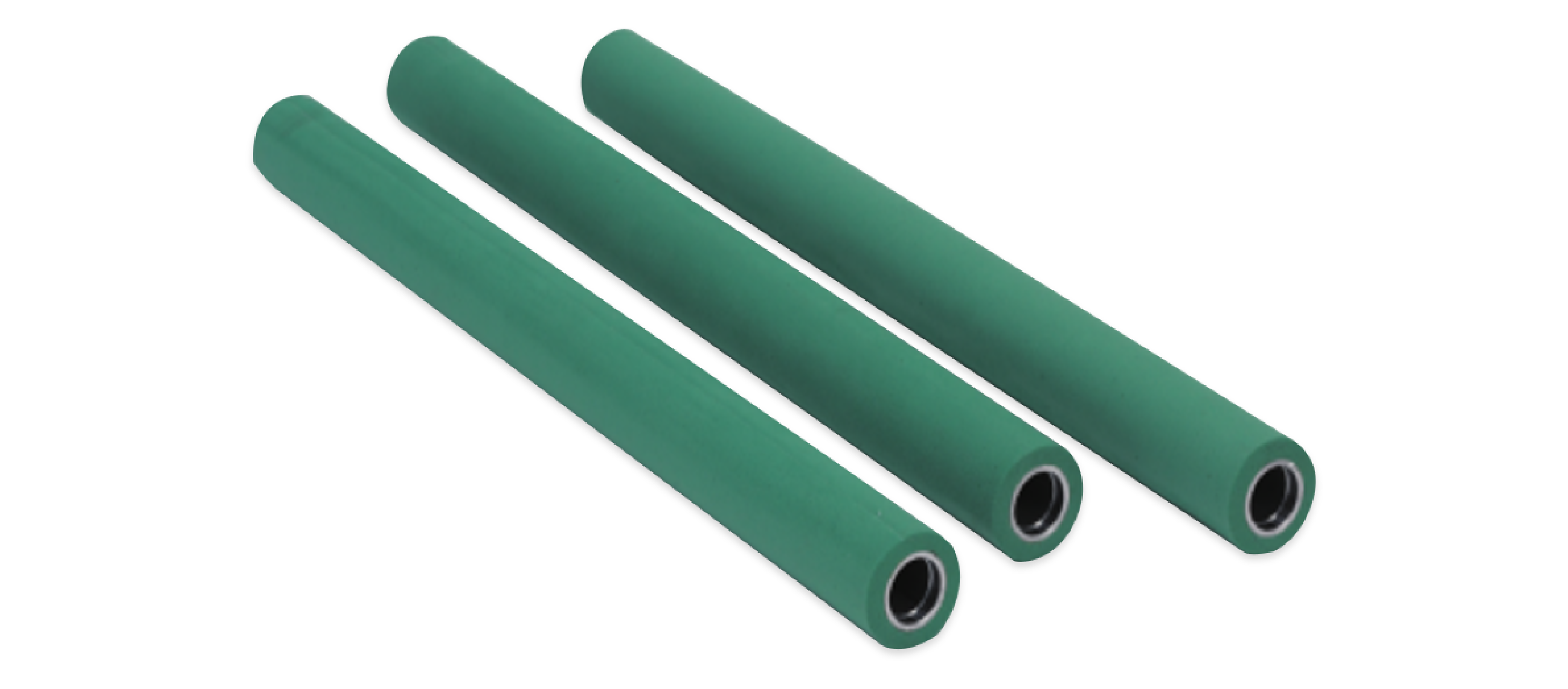

FORM ROLLERS

FORM ROLLERS

Form rollers are used a wide variety of application and industries.

We developed rollers that require extremely soft properties with wear resistance,

tensile strength, surface uniformity and long service life for tire production.

The form rollers typically manufactured using materials that offer the required

combination such as polyurethane, rubber and composite materials.

The form rollers in the tire production serve various functions in the tire building process which involve the assembly of the various components to form the final product, such as material application and consolidation, tread formation, sidewall shaping, bead formation, shoulder formation, layer alignment, etc.

The form rollers in the tire production serve various functions in the tire building process which involve the assembly of the various components to form the final product, such as material application and consolidation, tread formation, sidewall shaping, bead formation, shoulder formation, layer alignment, etc.

Saerim Tech Co., Ltd.

73, Pyeongdongsandan-ro Gwangsan-gu, Gwangju, KOREA 62419

Tel. +82 (0)62 952 2070 ㅣ Fax. +82 (0)62 952 2060 ㅣ Emil. srbdgood@hanmail.net

business license. 410-81-69879

China Qingdao Yonglin Building B/D Co., Ltd.

Xiangshan-Lu#6, Development Zone, Laixi, Qingdao, Shandong, China

Tel. +86 532 6689 3121 ㅣ Fax. +86 532 6689 3122 ㅣ Emil. srbdgood@hanmail.net